|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

On almost every new slate roof you will find

at least one ventilation slate that is connected to a soil pipe or

extractor fan, or that is installed to control condensation. Due to

plastic designs, the majority are now flush with the surface of the

roof, making them more inconspicuous.

Vent slates come in two generic types: those that lap

under the adjacent slates, and those that do not. Generally, those that

have hoods or mushroom caps on the top surface do not have side

flanges/channels, while most of those that have flush-fitting grills do

have them.

Flanges/channels

The flush-fitting grills require the bulk of the vent to be located

below the surface of the slate, and therefore the duct tends to take up

most, if not all, of the width of the raised central section of the

vent. The flanges/channels down either side of this section serve two

purposes: they help to hold down the slate at the leading edge, and they

provide additional side lap to the slate below, which has been cut to

allow the vent duct to pass through it.

The thickness of the flanges/ channels causes the adjacent

slates to kick up by their thickness, which is about 2mm on average.

Also, the flanges/channels are 25mm-50mm wide, so pass under the nail

hole position of the adjacent slate, forcing the nail fixing to be

driven through the flanges/channels, or a new nail hole to be punched

further from the edge of the adjacent slate. The raising of the adjacent

slate also reduces the penetration of the fixing nail by the same

amount. With fibre cement slates, the copper disc rivet fixing in the

adjacent slate will either cause the slate to bend slightly, or there

will be less of the rivet pin bent over the top surface – neither of

which is desirable.

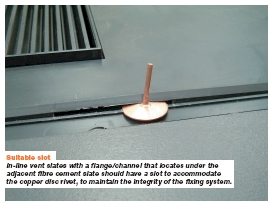

Many of the vent slates with flanges/channels are

designed for use with natural slates. With FC slates there is a need to

provide a copper disc rivet fixing to hold the leading edge of the

slates in the course above. Because the rivet needs to pass under the

two adjacent edges of the slates below, this is not always possible, as

the flange/channel being moulded into the vent slate removes one of the

two edges.

Opening up the side gap to accommodate the copper

disc will affect the coursing of the slates, and leave the rivet

unstable and able to rotate and pull out from under the adjacent slate.

Cutting off half the copper disc rivet eliminates one of these

requirements but not the other, so is also not acceptable. Notching the

rivet into the side of the adjacent slate and punching a new hole in the

tail of the slate above is a slightly better option, but weakens the

edge of both slates.

The best option is to use a vent slate

specifically manufactured for FC slate that has a slot built into it for

locating the copper disc rivet. Having flanges/channels down each side

makes it impossible to cut the vent slate to fit any other size of slate

than that which it has been manufactured for.

Butt edge

Vent slates with no flanges/channels down each side tend to have hoods

or mushroom caps on the top surface and a smaller duct through the

underside, making the side lap distance greater.

Butting up to the adjacent slates stops them kicking

up, provided that the overall thickness of the vent slate is the same as

– or less than – the adjacent slates. Also, there should be no

interference with the adjacent slate nail fixing, and the copper disc

rivet for the slates above should be accommodated without modification.

With no side flanges/channels, the leading edge of the vent slate should

be held down with a copper disc rivet or a slate hook, to prevent wind

uplift (regardless of the type of slate). |

|

Sizes

The majority of vent slates are designed to suit both 600mm x 300mm and

500mm x 250mm slates. While some natural slates in the UK are supplied

in these sizes, most are likely to be one of the 28 imperial sizes,

making some vent slates difficult or impossible to install with natural

slates. They would therefore be more suitable for use with FC slates,

provided the thickness is correct.

Colour and texture

Plastics, when new, can be produced to closely match the natural or FC

slate colour and texture, but they will never be the same, as the

materials will weather differently over time. Often, if they start off

different, the colour and texture may blend in better after a few years.

The precise finish, colour and texture of the plastic vent slates –

relative to the adjacent slates – is almost impossible to predict, so

colour and texture variations should be expected. Placing vent slates in

inconspicuous locations is therefore always a good idea.

Installation

All good vent slates will come with a set of fixing instructions, which

should be adhered to. They should always be laid to the correct half

bond with the surrounding slates. This may be difficult with some

designs where the exposed surface of the vent extends up over two

courses.

If the duct on the underside coincides with the

rafter or counter-batten position, the vent slate may have to be

installed in the course above. This may not always be possible where the

rafter centres are at below 450mm. If this is the case, a vent slate

with a narrow duct could be used, or the coursing of the slates on the

roof can be adjusted to ensure the vent slate is positioned at the mid

point between two rafters. For a very small variation, it may be

possible to trim the edges of the slate or the vent slate (if it does

not have side flanges/ channels), so long as it does not affect the

minimum side lap or the structure of the vent slate.

Where the slates on the course above and below

are cut to accommodate the duct on the underside, and the grill on the

top surface, the cuts should be as close to duct and grill as possible

without lapping over them and reducing the ventilation capacity.

Where the grills on the top surface are raised,

lapping onto the grill will cause the cut slates to kick up, and may

affect the nail or copper disc rivet fixing. Vent slates should never be

installed close to the perimeters of any roof slope. The closer they are

to the centre of the roof slope the better.

Tips

- Vent slates with side flanges/

channels need a disc rivet slot when used with FC slate.

- Use a vent slate with a narrow duct

where the rafter centres are less than 450mm.

- The leading edge of the vent slate

needs to be held down to prevent wind suction damage.

|

| Compiled

by Chris Thomas, The Tiled Roofing Consultancy, 2 Ridlands Grove,

Limpsfield Chart, Oxted, Surrey, RH8 0ST, tel 01883 724774 |

|