|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

|

|

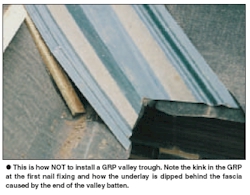

The most vulnerable part of any inclined valley is where it discharges

into the eaves gutter. This is equally true for GRP valley troughs, which

are the tilerís preferred valley liner due to ease of installation and

relative cost.

Unlike lead, GRP (glass reinforced

polyester) cannot be stretched or bent into shape. Whilst it can be bent a

little along its length (down the centre line), it is more difficult to

bend across its width, due to its general ĎVí shape. The ability to be

bent along its length is to allow the trough to fit a limited range of

roof pitches. The steeper the rafter pitch, the smaller the angle across

the valley (dihedral angle). If the valley trough is bent across its width

it is likely to stress or damage the corrugations that form the edge of

the trough. The corrugations provide rigidity to help it resist wind

uplift forces, once it is nailed into position. They also form channels to

take away water that may penetrate the mortar bedding, which is not 100

percent waterproof.

The rainwater flowing off the tiles into

the valley is added to that already flowing down the valley. This

continues until the maximum volume of water is reached at the bottom of

the valley, just before it discharges into the gutter, or back onto the

roof in the case of a dormer. At the point of maximum flow it is essential

that nothing obstructs the discharge of water. A reduction of the true

valley pitch will cause the water flow to slow down or develop turbulence.

This will act as a restriction to the water flow, which will in turn,

cause the water to back up the valley and spill out over the adjacent

tiles. |

|

| Placing the valley trough directly onto the top of the fascia board will

reduce the true valley pitch, as the height of the fascia is generally

about 50mm above the rafter level. This will also cause the outer

corrugations of the trough to kick up the eaves tiles on either side of

the valley by between 19 and 25mm. Whilst this looks less than

professional, it also reduces the weatherability of the roof covering by

creating gapping between the tiles.

To prevent this happening, the fascia board

should be cut down by at least the height of the GRP trough corrugations

(25mm) for the full width of the valley; this is to allow water in the

side channels to discharge into the gutters. If the fascia is cut down by

more than 25mm it will affect the position of the guttering, which in turn

could allow water flowing of the roof to discharge over the gutters.

Cutting down the height of the fascia board

should be the responsibility of the carpenter but it is inevitably left to

the tiler to do. Whilst this is more work for the tiler, installing a GRP

valley is a far simpler operation than forming a lead valley. Provided the

GRP valley is installed correctly the life expectancy of the roof should

not be compromised.

|

| Compiled by Chris Thomas, The Tiled

Roofing Consultancy, 2 Ridlands Grove, Limpsfield Chart, Oxted, Surrey,

RH8 0ST, tel 01883 724774. |

|