|

|

|

|

|

|

|

|

Check out our web directory of the UK

roofing and cladding industry

www.roofinfo.co.uk |

Sign up for our monthly news letter. |

|

|

|

'Keep it simple' is a good principal for

all things in building. But with pitched roofing it should be extended

to 'keep pitches equal'; it eliminates so many problems and looks better

into the bargain.

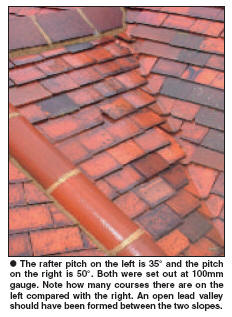

With plain tiles it is possible to course around at valleys and hips

from one roof slope onto another, making a clean and low maintenance

roof covering. But this only works if the rafter pitches are equal on

all slopes, or within a few degrees. If outside these parameters,

purpose made standard bonnet/arris hips or curved/arris valley tiles

will not fit. In these circumstances, open lead valleys or ridge/hip

tiles should be used to form the junction.

The reason for the need for

equal rafter pitches relates to the length of the rafter and the number

of tile courses over a given vertical rise between fixed points. Put

simply, if two roof slopes start and finish at the same eaves and ridge

level, the rafter with the lower pitch will be longest, needing more

courses of tiles, resulting in a mismatch at the hip or valley junction.

This can be compensated slightly by setting the lowest rafter pitch to

the maximum gauge (100mm), and closing down the gauge on the steeper

slopes to give the same number of tile courses.

This sounds simple but there are some

conditions that need to be understood:

-

The smallest batten

gauge must not fall below 88mm gauge. This provides only 12mm of

head lap variation. Therefore the difference between the steepest

rafter pitch and the shallowest need to be close. The actual number

of degrees will depend on the actual angle of the lowest rafter

pitch.

-

Fixed setting out points

on one slope will be transferred onto each roof slope and further

affect the batten gauge restriction.

-

All standard bonnet/arris

hip and curved/arris valley tiles are made to fit equal rafter

pitches on a 90° plan angle. They may have some slack in the fit to

allow up to 2° of difference between slopes. Beyond that limit the

dihedral angle between the two rafter slopes will result in the

tiles kicking in or out, leaving gaps for wind and rain to get in

and making the roof look untidy.

-

An eaves sprocket on one

roof slope only, such as with a dormer meeting a main roof slope,

will result in the line of the valley changing direction. Hip and

valley tiles are only designed to be laid in a straight line and not

designed to turn corners.

-

Some roof slopes may

vary in pitch from one end to the other, or have a hump in the

middle. This will require the battens to be laid to a tapered (not

fixed) gauge, and must not exceed 100mm or drop below 88mm.

|

|

-

Some clay tile

manufacturers are willing to make special hip and valley tiles to fit

unequal rafter pitches. To fit correctly, not only the rafter pitch

but also the batten gauge needs to be known and considered during the

design stage. This may not be possible to determine prior

to battening out the roof. Special hip and valley tiles are

expensive, take time to manufacture and may delay the contract.

-

Where a large roof is

being clad with tiles on one slope, whilst the roof has yet to be

constructed on another elevation, it may not be possible to

determine which is the actual lowest pitched rafter slope before

setting out the first roof slope.

Whilst points 3 and 4 could be solved by

cutting tiles to a mitered valley/hip with lead soakers, there is a

minimum rafter pitch restriction of 45° with mitered valleys and 52.5°

with mitered hips provided the plan angle of the junction is 90°. Below

these figures a tile and a half will not be wide enough to form the cuts

allowing for two head nail fixings.

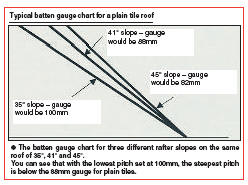

To determine the scale of the problem and

where it will, or will not be possible to adjust the gauge or use

standard valley/hip tiles, each part of each roof slope needs to be

accurately measured to provide the rafter pitch to within half a degree.

From this information a batten gauge chart needs to be drawn up (see

diagram) by drawing each rafter pitch out from a common origin. The

maximum gauge is then marked out on the lowest rafter pitch. From the

gauge position a horizontal line is drawn through each of the other

rafter pitches. Measuring up from the origin, the gauge for each rafter

pitch can be determined:

- Where the rafter pitches vary more

than 2°, purpose made valley and hip tiles may not fit, or special

tiles may be needed.

- Where the gauge falls below 88mm, the

roof slope will need to be separated using an open valley or ridge

hip tile.

- A group of roof slopes may be selected

for a further batten gauge chart, such as a hexagonal bay or dormer,

separated from the main roof by an open lead valley.

- Over 10 courses the batten gauge

should not gain or loose more than 5mm and be adjusted to ensure

there is not an accumulative error over the total rafter length.

Millimeters are much more accurate than using imperial measurements.

With this

information the roof can be set out accurately to ensure the top of all

battens on the same course meet precisely on the centre line of each hip

and valley, except where open lead valleys or ridge hip tiles are used.

Whilst it can be done, it needs a lot or patience, accurate measurement

and cutting, and a specifier who understands the limitations of plain

tiles and fittings.

It is easier and cheaper to design and

construct all the rafter pitches to the same pitch but may not look as

interesting to an architect. |

|

Compiled by Chris Thomas, The Tiled

Roofing Consultancy, 2 Ridlands Grove, Limpsfield Chart, Oxted, Surrey,

RH8 0ST, tel 01883 724774 |

|