|

Photovoltaics have the greatest documented

technical potential for generating electricity of all the renewable energy

sources in Europe. The trend is definitely in the direction of the so called

BIPV – Building Integrated Photovoltaics – and these can be integrated

directly as solar components with multiple functions such as sunshades,

facade cladding or roofing, thus affording other green benefits. |

|

|

Photovoltaics (PV) represent an increasingly

important type of renewable energy, thanks to rising interest in and demands

on the environment and advances in solar technology supported by subsidised

programmes. |

|

The importance of PV in architecture is also

changing, the main criteria being the desire for design freedom and a

balanced appearance of the system. While PV thinking is usually strongly in

the direction of tilted, framed crystalline modules, which are difficult to

match with the preferences of many planners and architects, the trend today

is towards architectonically integrated systems that are generally based on

more modern, thin film technology. |

|

Applications |

|

Modern BIPV do not necessarily have to be the

aspect that determines the design for architecture. Quite the contrary.

Intelligent solar energy systems can be integrated in the planned

construction project such that they are easily visible or hidden, depending

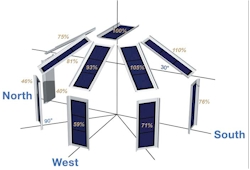

on the customer’s wishes.In general, all roof surfaces facing southwest to

southeast in central Europe are suitable for PV applications. However, BIPV

can also be used for north-facing shallow-sloped roofs if the usable areas

of the shells in the roof and facade are designed to ensure optimum sunlight

exposure without shading. In case of doubt, computer-aided simulation can

help ascertain the right solution. |

| Thin

film modules are commonly employed in the integration of PV in buildings and

compared to the better known crystalline modules, have not just a

significant weight advantage. This technology is especially suitable for

weak or diffused light because the usual mounting supports for the modules

are no longer required. |

| In general, the

roof is the part that is most exposed to weather and environmental

influences. Classic, sustainable roof planning, with all the constructive

and physical requirements in terms of waterproofing and durability, must not

be neglected. |

|

| Ideally therefore,

well-proven roof systems should be used where the PV cells/modules are

integrated into the roof skin but also where the original roof is

technically separate from the PV itself |

| The

number of metal or plastic flat or pitched roofs that satisfy this

requirement is increasing but the system used should fulfill the following

five criteria: |

- The roof system is supervised and

approved and its functions have been tried and tested on the market.

- Solutions that satisfy the relevant

standards and that have technically proven themselves are available for

all planning and implementation problems, especially in the case of

details and connections.

- The functioning (or as the case may be,

the failure) of the PV modules does not affect the structural and

physical properties of the roof.

- The BIPV system demonstrably fulfills

the requirements of protection class II (Electrical Safety during

Assembly and Operation) and IEC 61646/IEC 61215 (Suitability and

Durability of Photovoltaic Modules).

- The materials, construction and

implementation of the roof system ensure the proper operation of the PV

system over the expected PV service life. Current experience has shown

this is approximately 35 to 40 years. This also means future expected

maintenance or repair work should not affect the functioning of the PV

system or, in the worst case, lead to a failure.

|

| A

feature shared by BIPV thin film systems used today is the favorable energy

payback time. While the usual systems based on crystalline modules have an

energy payback time of about 10 years, that of current thin film systems is

approximately two years.The difference is based mainly on the more spared

use of the primary material - silicon. In the most commonly used module type

made of amorphous silicon (a-Si), the required silicon layer thickness is

less than 100th of the layer thicknesses in crystalline framed cells. This

property is also the reason for the malleability and flexibility of many

BIPV systems. |

| At the same time,

this characteristic means that the surface efficiency of thin film modules

is usually lower than the comparable values of crystalline modules. As a

result, a smaller system (ie. a lower kWp capacity) should be installed. |

|

| Thin film modules

based on cadmium telluride (CdTe) are still not often used - they are

controversial due to the use of the heavy metal cadmium and stringent safety

and environmental regulations must be satisfied in the production phase. |

| In

technical circles, copper indium diselenide (CIS) modules have long been

considered as being a determining influence because higher efficiencies are

being targeted for the future. Until now however, the difficulty concerning

this module type has lain in setting up the very complex system technology

for mass production. |

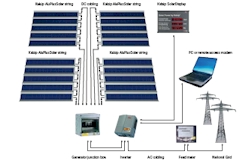

| Dr

Jürgen Neuwald is director of new business and technology for Kalzip Ltd,

for more information see

www.kalzip.com |